P-Hydroxybenzaldehyde

Product name: 4-Hydroxybenzaldehyde

p-Hydroxybenzaldehyde;

PHBA;

CAS No.: 123-08-0

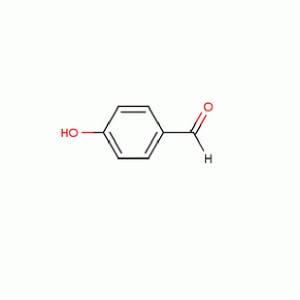

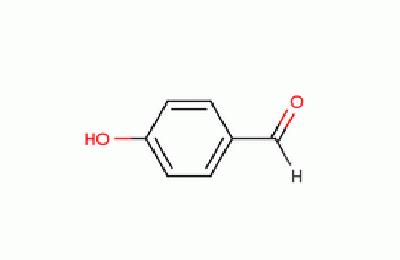

Molecular formula: C7H6O2

Molecular weight: 122.1213

Structural Formula:

Density: 1.226g/cm3

Uses:It is important fine chemical product and intermediate for organic synthesis, with wide use in pharmaceutical, aromatizer, pesticide, electroplating and liquid crystal industries. In pharmaceutical industry, it can be used to synthesize intermediates of sulfonamides such as broad-spectrum sterilization synergist TMP, ampicillin and semi-synthesized penicillin (oral) as well as intermediate of d-(-)-p-hydroxy phenyl picramate. In aromatizer industry, it is mainly used in raspberry ketone, methyl vanillin, ethyl vanillin, anisic aldehyde and nitrile aromatizer. In pesticide industry, it is mainly used to synthesize new-type insecticide, herbicide, o-bromobenzonitrile and hydroxyl casoron. In electroplating industry, it can be used as a new-type cyanogens-free electroplating brightener.

|

Index name |

Index Value |

||

|

Appearance |

Electron Grade |

Medical Grade |

Spices Grade |

|

white crystalline powder |

Pale yellow crystalline powder |

Pale yellow crystalline powder |

|

|

Purity :% |

≥99.8 |

≥99.5 |

≥99 |

|

Moisture:% |

≤0.3 |

≤0.3 |

≤0.5 |

|

Melting point:℃ |

115.5~118 |

115~118 |

114.5~116.5 |

|

Chloride:PPm |

≤50 |

≤50 |

|

|

Heavy metal: PPm |

≤8 |

≤8 |

|

|

Insoluble % |

≤0.05 |

≤0.05 |

|

1.There are many processes for the production of p-hydroxybenzaldehyde. At present, the industrial production mainly includes phenol, p-cresol, p-nitrotoluene and other raw materials.

2.The phenol method can be divided into Reimer Tiemann reaction, gattermann reaction, phenol Trichloroacetaldehyde route, phenol glyoxylic acid route, phenol formaldehyde route, etc. Phenol process is characterized by easy access to raw materials, simple manufacturing process, low yield and high cost.

The process of p-nitrotoluene to produce p-hydroxybenzaldehyde includes three steps: oxidation-reduction, diazotization and hydrolysis.

3.P-cresol catalytic oxidation the process is to directly oxidize p-cresol to p-hydroxybenzaldehyde with air or oxygen under the action of catalyst.

The specific process flow is as follows: add p-cresol, sodium hydroxide and methanol into stainless steel pressure vessel, stir until it is completely dissolved, add cobalt acetate to seal the reactor, raise the temperature to 55 ℃ and start to introduce oxygen, keep the pressure in the vessel at 1.5MPa and react for 8-10h, strictly control the oxygen flow rate in the reaction process, and install coil cooling system in the vessel, when the temperature rises, the jacket of the vessel will be provided The cooling water can be connected. At this time, the coil begins to be connected with cooling water, strictly control the total amount of oxygen, and keep the temperature in the kettle at about 60 ℃. At the end of the reaction, the material is put into the primary autoclave, the solvent methanol is evaporated and recycled, and hydrochloric acid is added after water is added for salting out. The solid-liquid material is filtered by a centrifuge, and the solid obtained is dried in a vacuum oven at about 60 ℃ for 3-5h, then p-hydroxybenzaldehyde with content more than 98% can be obtained.